Anferra Advances Recycling Technology with Successful Demonstration Project

Reaching 95% Iron Recycling Rate for Industrial Steel Waste with Support from SKF and Scania

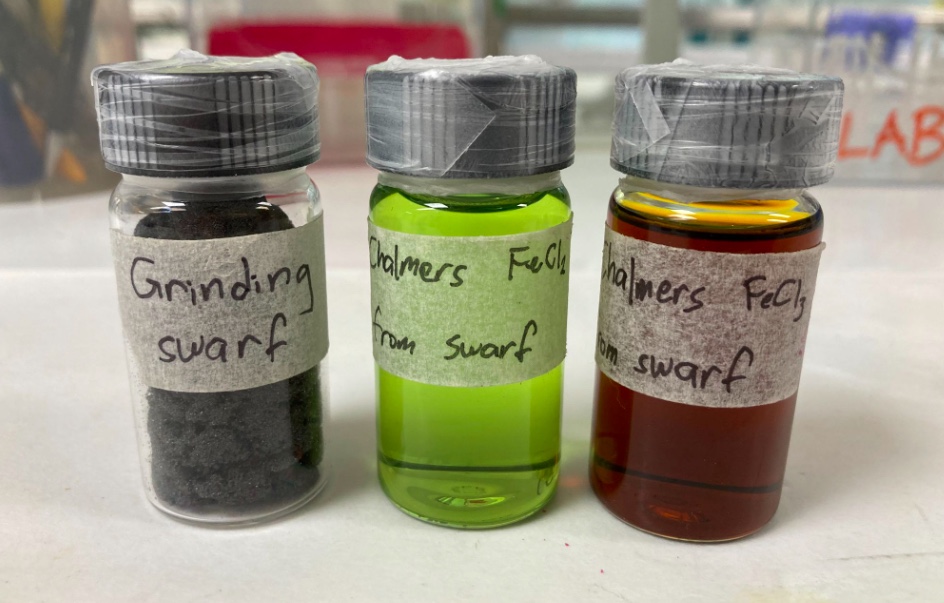

In June, Anferra successfully completed a demonstration at a larger batch scale, showcasing the effectiveness of our innovative recycling process. With financial support from SKF Group and Scania Group, we achieved an 95% recycling rate of the iron in the grinding swarf, demonstrating the potential for a more sustainable solution to managing industrial steel waste.

Advancing to TRL 5: A Significant Milestone

This pilot advanced key parts of our recycling process to Technology Readiness Level (TRL) 5, validating it in a relevant, real-world setting. Using grinding swarf provided by SKF and Scania, we produced high-purity iron chloride, meeting European standards for drinking water treatment. This marks an important step toward commercializing our solution for broader industrial use, turning hazardous waste into valuable, essential chemicals.

Partner Feedback: Words from SKF and Scania

Linda Widbro, Business Development Manager at SKF Group:

“Great job, by a great team. Looking forward to the next steps and seeing how this can support the industry in becoming more ‘Intelligent and Clean’ at scale. Industrial companies like SKF and many others are seeking new alternative processes to minimize waste, landfill, and incineration.”

Maria Bodingh Johansson, Engineering Expert Environmental Sustainability at Scania Group:

“So happy and proud to be part of the work you do. You give me hope that we can solve many of the existing challenges through new innovations, a wealth of ideas, and cooperation between large and small actors. Thank you for being so amazing and giving us the opportunity to be part of this journey, continuously improving towards a sustainable future.”

Both quotes highlight the crucial role of collaboration in advancing sustainability and innovation. Working closely with partners like SKF and Scania, Anferra is moving toward providing industries with a circular solution for hazardous waste—one that not only reduces landfill but turns industrial byproducts into valuable resources.

Looking Ahead: Scaling for Broader Industrial Impact

This successful demonstration brings us closer to scaling our technology for large-scale industrial applications. Our process helps industries like steel manufacturing reduce their environmental footprint while contributing to essential resources such as clean water.

We extend our sincere thanks to SKF Group and Scania Group for their collaboration and support.